Used exclusively in the CLR Asphalt Late Model. The DEI Floor & Tunnel Shield II™ solves the problem of needing a high heat barrier to block heat from any source intruding into interiors and damaging components and electronics.

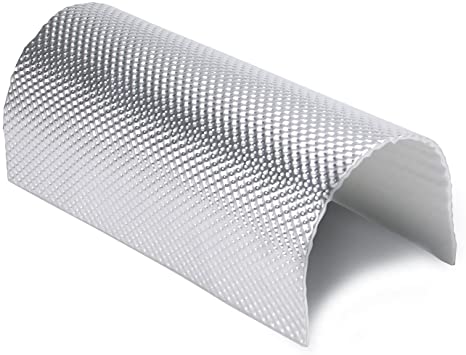

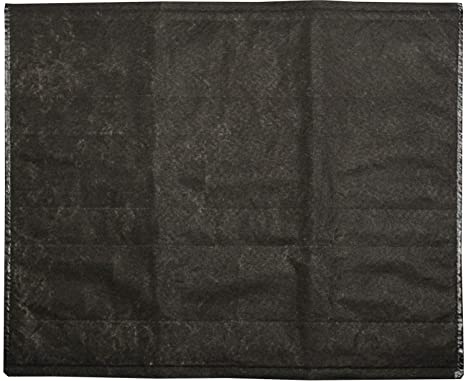

Use as a barrier to reflect and insulate from any heat source. Designed to provide the best possible heat protection in areas where high temperatures are always present and problematic, Floor & Tunnel Shield II limits heat transfer on fire walls, transmission tunnels, floor boards, fuel cells, and other areas where heat is an issue. Floor & Tunnel Shield II provides excellent lightweight thermal protection, acts as a guard against track and road debris, and provides sound deadening as well. Constructed with an embossed 10 mil aluminum face bonded to a 1/8" composite glass-fiber core and backed with a high temp super strong pressure sensitive backing, Floor & Tunnel Shield II withstands up to 1750°F. The adhesive side holds past 450°F. Its improved multifaceted modern aluminum surface offers improved reflection and rigidity and allows for ease of installation - the aluminum side must face the heat source. At only 3/16" thick, this product can be shaped and trimmed for a custom fit and is ideal for minimal clearance areas. With a unique and patented finely woven glass-fiber backing, Floor & Tunnel Shield II is the easiest, most cost-effective way to control thermal transfer while protecting expensive components and vehicle occupants from extreme heat situations and sound. Floor & Tunnel Shield II can be used on any number of surfaces including, metal, aluminum, carbon fiber, plastic, and more. Multiple uses include: fire walls, under hoods, transmission tunnels, floor pans, fuel cells, and exterior under vehicle locations - anywhere to reflect damaging heat.

- 10 mil dimpled aluminum face

- Protection for engine compartments

- Protection for painted body parts

- Comfortable interior at any temperature

- Hi-temp adhesive for a "do-it-once" install

- Extreme heat barrier - aluminum side should face the heat

- Only 3/16" thick

- Use as a barrier to reflect and insulate from any heat source

- Great for exterior applications

- Backing: Adhesive

Direct Heat Resistance: 1750°F

https://youtu.be/a-9jiHSrRIM